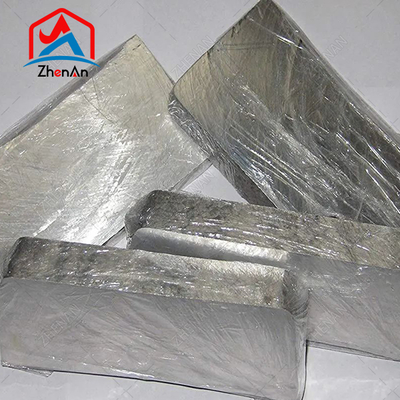

Magnesiumbarren - Hohe Reinheit für zuverlässige Legierungsanwendungen

In der Welt der Metalllegierungen hängen Konsistenz und Leistung von der Reinheit der Rohstoffe ab. Unser hochreiner Magnesiumbarren (99,5 %-99,99 %) wurde entwickelt, um unübertroffene Zuverlässigkeit zu gewährleisten und ihn zum Eckpfeiler der Premium-Legierungsproduktion in allen Branchen zu machen.

Hergestellt durch ein proprietäres mehrstufiges Raffinationsverfahren – das Vakuumdestillation, Elektro-Raffination und Inertgas-Gießen kombiniert – eliminieren unsere Magnesiumbarren kritische Verunreinigungen wie Eisen, Nickel und Kupfer auf Werte von bis zu 0,0005 %. Diese Präzisionsreinigung gewährleistet eine gleichmäßige Kornstruktur, erhöhte Korrosionsbeständigkeit und überlegene mechanische Eigenschaften, einschließlich einer Zugfestigkeit von bis zu 400 MPa und einer Dehnung von über 10 % in legierter Form. Für Hersteller bedeutet dies weniger Materialverschwendung, eine längere Werkzeuglebensdauer und die Fähigkeit, komplexe Komponenten mit hoher Toleranz und minimaler Nachbearbeitung herzustellen.

Die einzigartigen Vorteile von hochreinem Magnesium zeigen sich in Anwendungen, die Haltbarkeit und Leichtbauweise erfordern. In der Luft- und Raumfahrt verstärkt es Aluminiumlegierungen für Flugzeugrahmen; in der Automobilindustrie verbessert es Magnesiumlegierungsräder und Getriebegehäuse. Selbst im Schiffbau, wo Korrosionsbeständigkeit von größter Bedeutung ist, bilden unsere Barren Legierungen, die rauen Salzwasserumgebungen standhalten.

Jede Charge, die nach ISO 636 und ASTM B94 zertifiziert ist, wird strengen Tests mittels ICP-MS und GDMS unterzogen, um Reinheit und Zusammensetzung zu überprüfen. Egal, ob Sie Legierungen der nächsten Generation entwickeln oder die Produktion skalieren, unsere hochreinen Magnesiumbarren bieten die Konsistenz und Leistung, die erforderlich sind, um die Industriestandards zu übertreffen. Vertrauen Sie auf ein Material, das Innovationen antreibt – denn Zuverlässigkeit beginnt mit Reinheit.

Spezifikationen

| Modell |

Mg (% Min) |

Fe (% Max) |

Si (% Max) |

Ni (% Max) |

Cu (% Max) |

Al (% Max) |

Mn (% Max) |

| Mg9998 |

99.98 |

0.002 |

0.003 |

0.002 |

0.0005 |

0.004 |

0.0002 |

| Mg9995 |

99.95 |

0.004 |

0.005 |

0.002 |

0.003 |

0.006 |

0.01 |

| Mg9990 |

99.90 |

0.04 |

0.01 |

0.002 |

0.004 |

0.02 |

0.03 |

| Mg9980 |

99.80 |

0.05 |

0.03 |

0.002 |

0.02 |

0.05 |

0.06 |

Verfügbare Größen:

7,5 kg ±0,5, 5 kg ±0,5, 12 kg ±0,5, 14 kg ±0,5 (Sondergrößen auf Anfrage erhältlich)

Verpackung & Lieferung

Standardverpackung:

1T/1,25T-Bündel, in Kunststofffolie verpackt und mit Stahlbändern auf Holzpaletten befestigt.

Lieferzeit:

10-20 Tage nach Erhalt der Vorauszahlung.

Unsere Leistungen

- Erfahrenes Fachpersonal

- Umfassende Zertifizierung bereitgestellt

- 24/7 Kundenbetreuung

- Anpassbare Verpackung und Partikelgröße

- Qualitätsgarantieprodukte

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!